Make mismatched bulbs and fittings work together with quality lamp holders and socket adapters. Explore E27, E14,...

Search in blog

Blog categories

Blog tags

Photo gallery

-

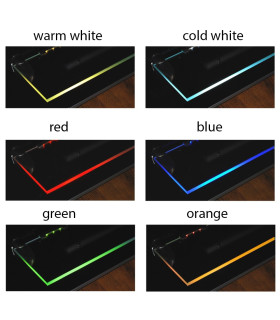

LED Lighting Colour Temperature Comparison

-

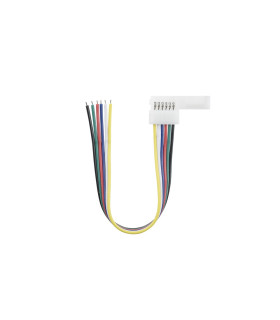

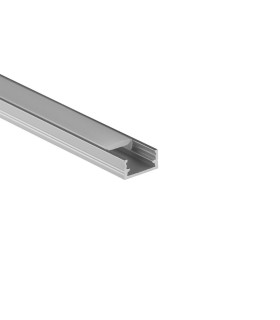

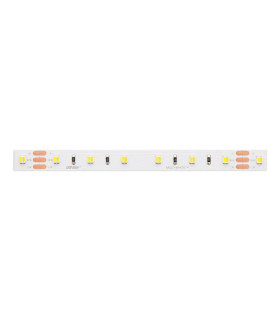

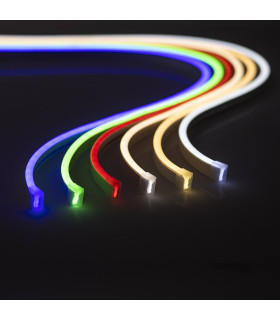

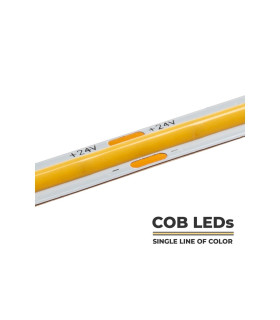

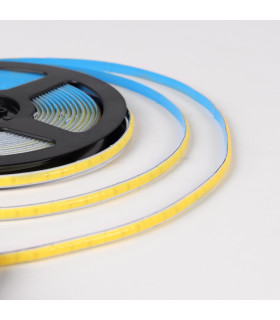

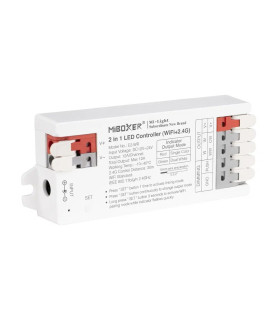

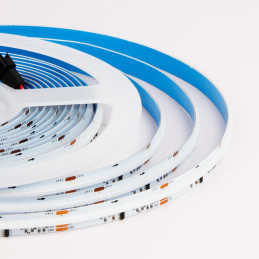

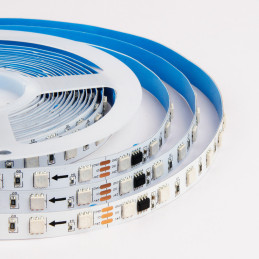

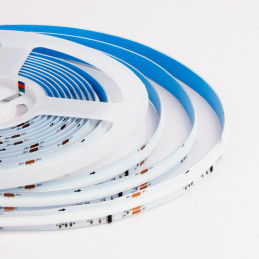

Flexible LED Strip Lighting

-

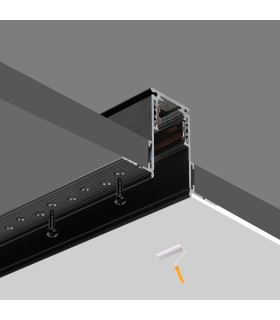

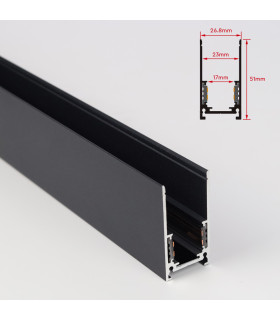

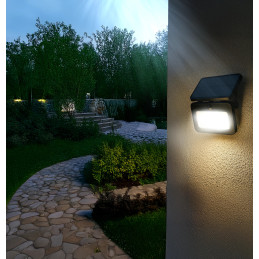

Modern LED Lighting Ideas for Home Interiors

Latest comments